D&D ELITE POWER DRIVE BELTS

Our premier line of high-performance cogged V-belts and timing belts are designed to meet the highest standards of quality and reliability.

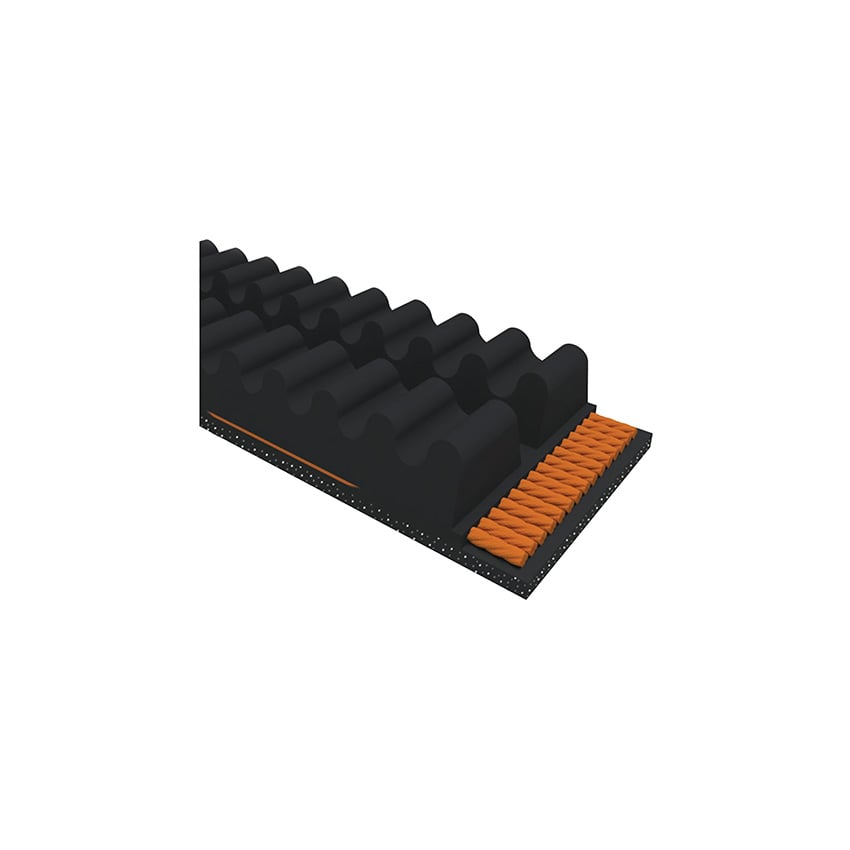

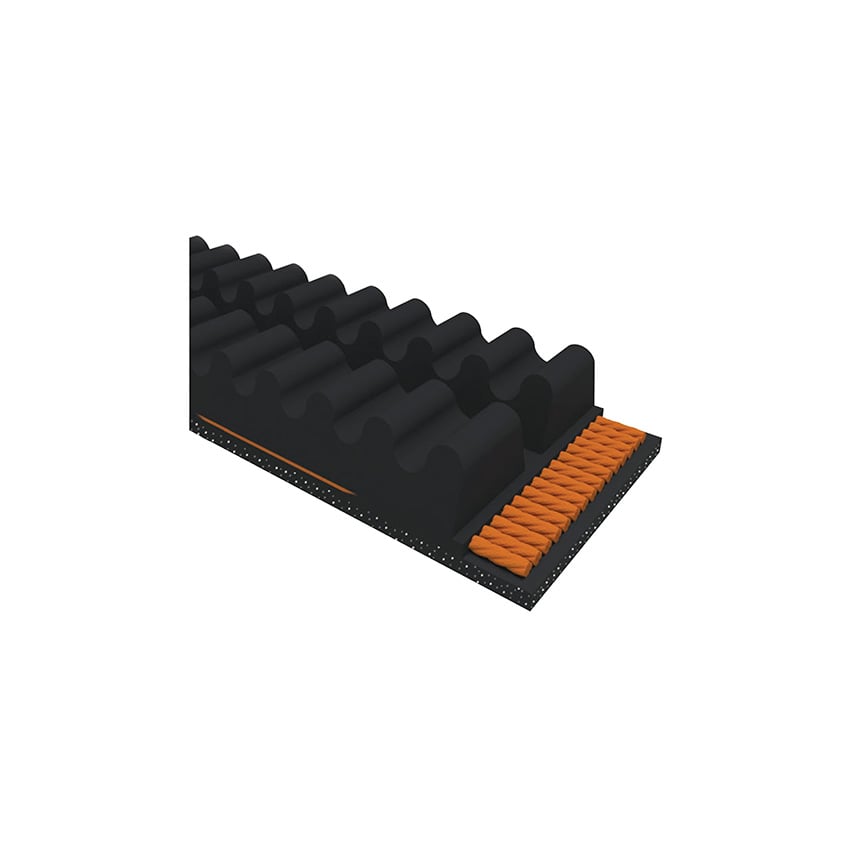

D&D Elite Cogged V-Belts

D&D Elite Cogged V-Belts are produced with Generation 3 manufacturing, using advanced production processes focused on improving quality control, automation, and performance. Engineered with high-quality EPDM rubber to resist high heat and oil, with a temperature rating of -67°F to 266°F, their flexibility reduces the risk of cracking, offering better performance in demanding conditions.

Our Elite EPDM belts can replace all popular USA standard and metric belt cross sections. They are Reach and RoHS compliant, and meet DIN7753 Belt Standards.

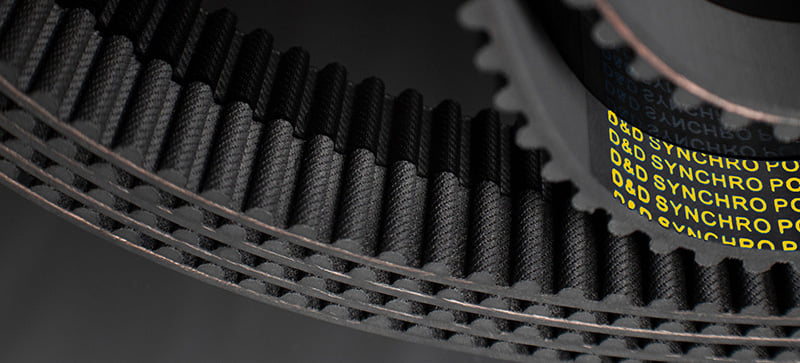

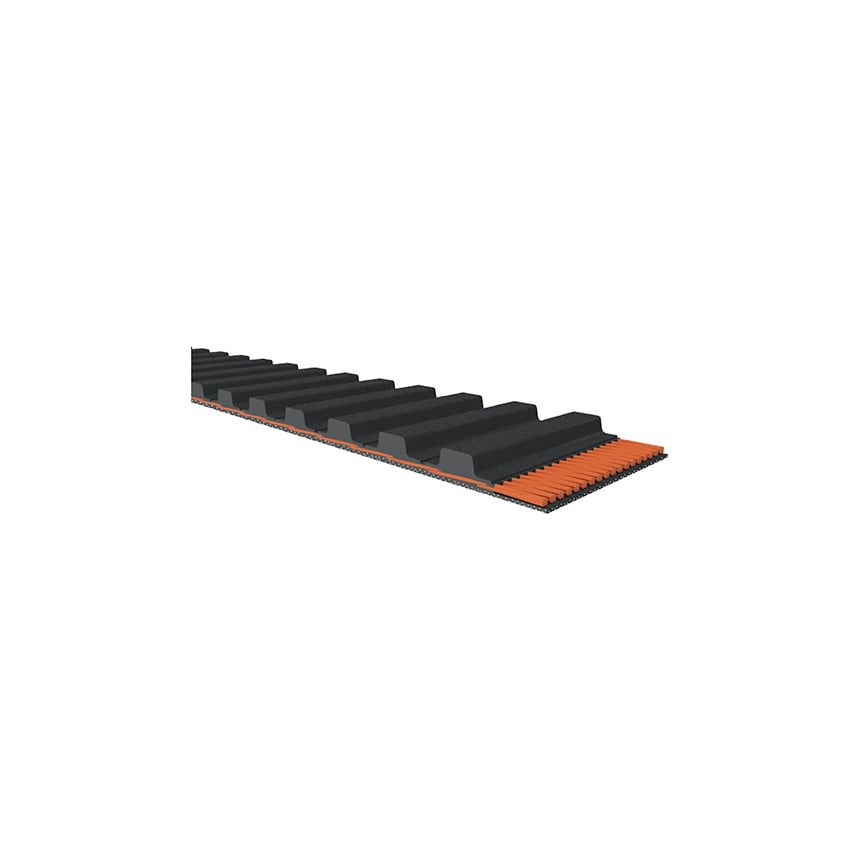

D&D Elite Timing Belts

D&D Elite Timing Belts are produced with Generation 3 manufacturing, using advanced production processes focused on improving quality control, automation, and performance.

This precision production creates belts better suited for high speeds and more efficient power transmission, enhancing performance. Elite belts primarily have better heat resistance and flexibility, extending their lifespan in harsh operating conditions.

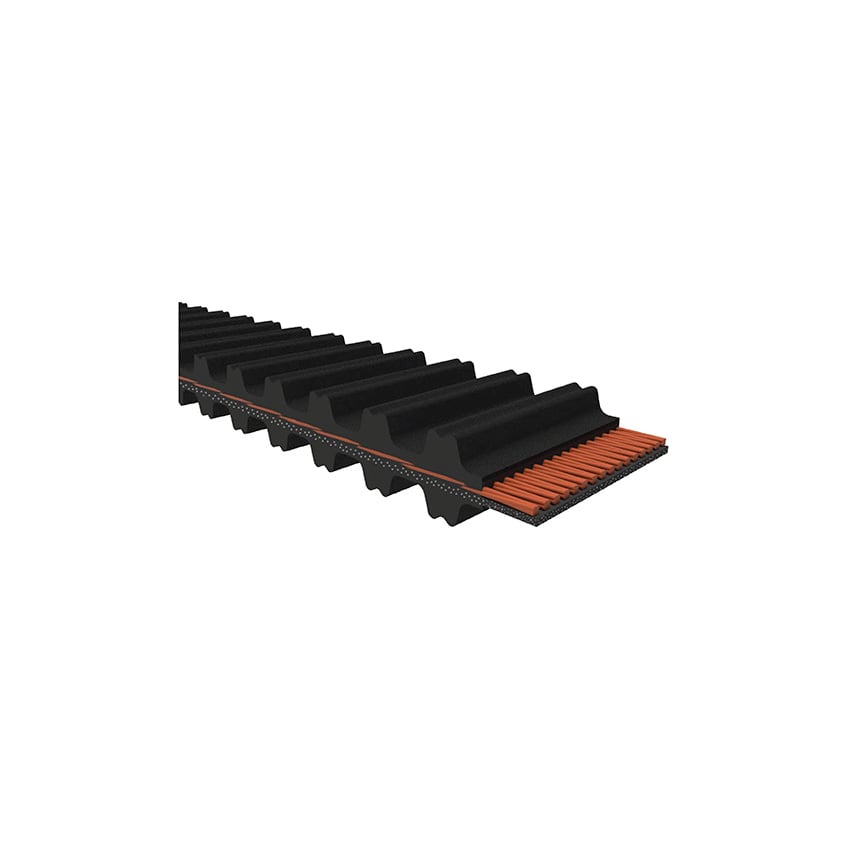

ELITE-EXTREME COGGED V-BELTS

Elite-Extreme Classical

AX

BX

CX

Elite-Extreme Classical

D&D ELITE-EXTREME CLASSICAL belts meet or exceed USA RMA published rating levels. They are manufactured to perform at identical or higher levels than all major US manufacturer’s belts of the same type.

Dimensions:

AX-E = 1/2” x 5/16”

BX-E = 5/8” x 7/16”

CX-E = 7/8” x 17/32”

Elite Cogged V-Belts are engineered with high-quality EPDM rubber to resist high heat and oil. Their flexibility reduces the risk of cracking, offering better performance in demanding conditions. Elite belts are produced with Generation 3 Manufacturing and are designed to be reliable and efficient in high-speed operations and in transmitting large amounts of power. Our belts are Reach and RoHS compliant and meet DIN2215+RMA IP-20 Belt Standards.

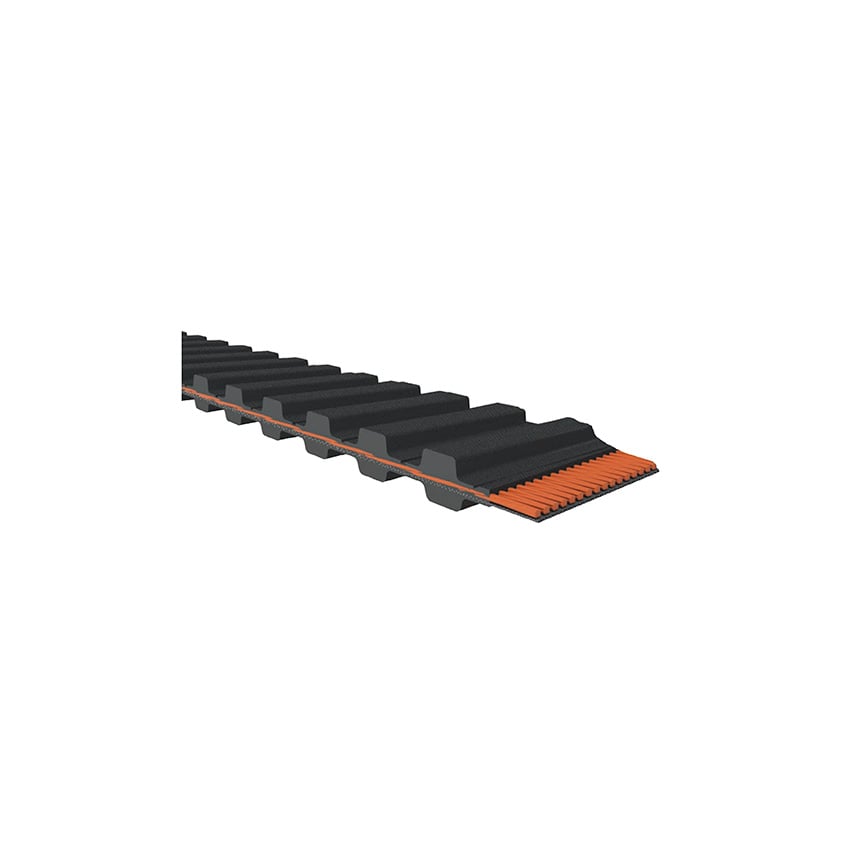

Elite-Extreme Wedge

3VX

5VX

8VX

Elite-Extreme Wedge

D&D ELITE-EXTREME WEDGE belts meet or exceed USA RMA published rating levels. They are manufactured to perform at identical or higher levels than all major US manufacturer’s belts of the same type.

Dimensions:

3VX-E = 3/8” x 21/64"”

5VX-E = 5/8” x 35/64”

8VX-E = 1” x 7/8”

Elite Cogged V-Belts are engineered with high-quality EPDM rubber to resist high heat and oil. Their flexibility reduces the risk of cracking, offering better performance in demanding conditions. Elite belts are produced with Generation 3 Manufacturing and are designed to be reliable and efficient in high-speed operations and in transmitting large amounts of power. Our belts are Reach and RoHS compliant and meet RMA IP-22 Belt Standards.

Elite-Extreme Metric

XPZ

XPA

XPB

XPC

Elite-Extreme Metric

D&D ELITE-EXTREME METRIC belts meet or exceed USA RMA published rating levels. They are manufactured to perform at identical or higher levels than all major US manufacturer’s belts of the same type.

Dimensions:

XPZ-E = 10MM x 8MM

XPA-E = 13MM x 10MM

XPB-E = 17MM x 13MM

XPC-E = 22MM x 18MM

Elite Cogged V-Belts are engineered with high-quality EPDM rubber to resist high heat and oil. Their flexibility reduces the risk of cracking, offering better performance in demanding conditions. Elite belts are produced with Generation 3 Manufacturing and are designed to be reliable and efficient in high-speed operations and transmitting large amounts of power. Our belts are Reach and RoHS compliant, and meet DIN7753 Belt Standards.

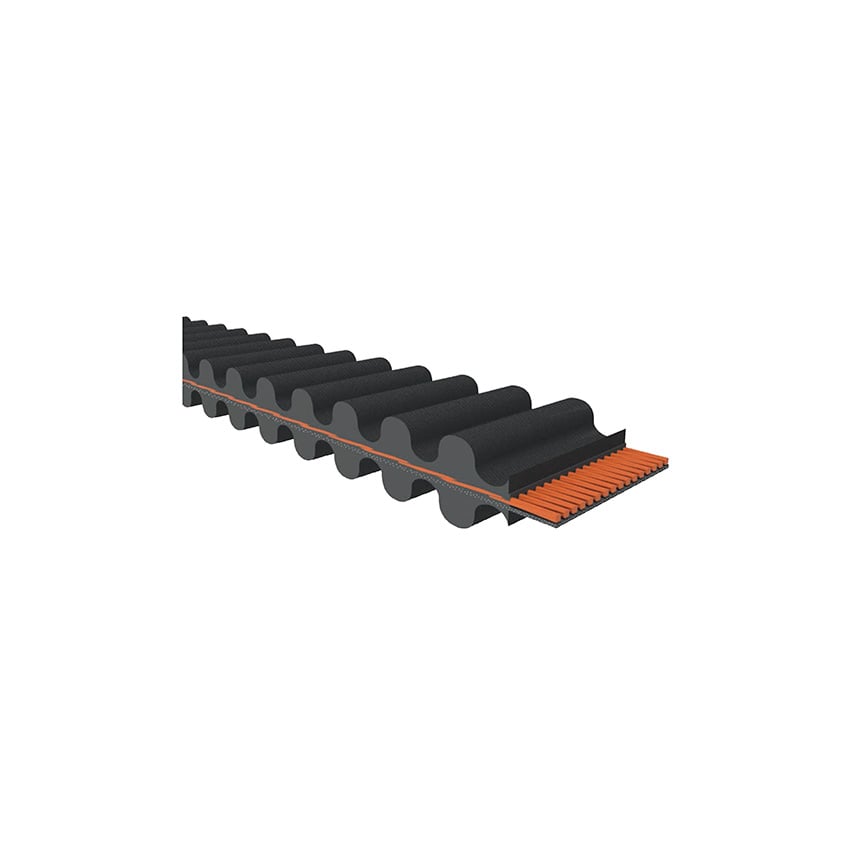

Elite-Extreme Band Classical

AX Band

BX Band

CX Band

Elite-Extreme Band Classical

D&D ELITE-EXTREME BAND CLASSICAL belts meet or exceed USA RMA published rating levels. They are manufactured to perform at identical or higher levels than all major US manufacturer’s belts of the same type.

AX Band <112’’: 2-8 bands

AX Band >/=112’’: 2-8 bands

BX Band <110’’: 2-6 bands

BX Band >/=110’’: 2-6 bands

CX Band <108’’: 2-5 bands

CX Band >/108’’: 2-5 bands

Elite Cogged V-Belts are engineered with high-quality EPDM rubber to resist high heat and oil. Their flexibility reduces the risk of cracking, offering better performance in demanding conditions. Elite belts are produced with Generation 3 Manufacturing and are designed to be reliable and efficient in high-speed operations and transmitting large amounts of power. Our belts are Reach and RoHS compliant, and meet DIN7753 Belt Standards.

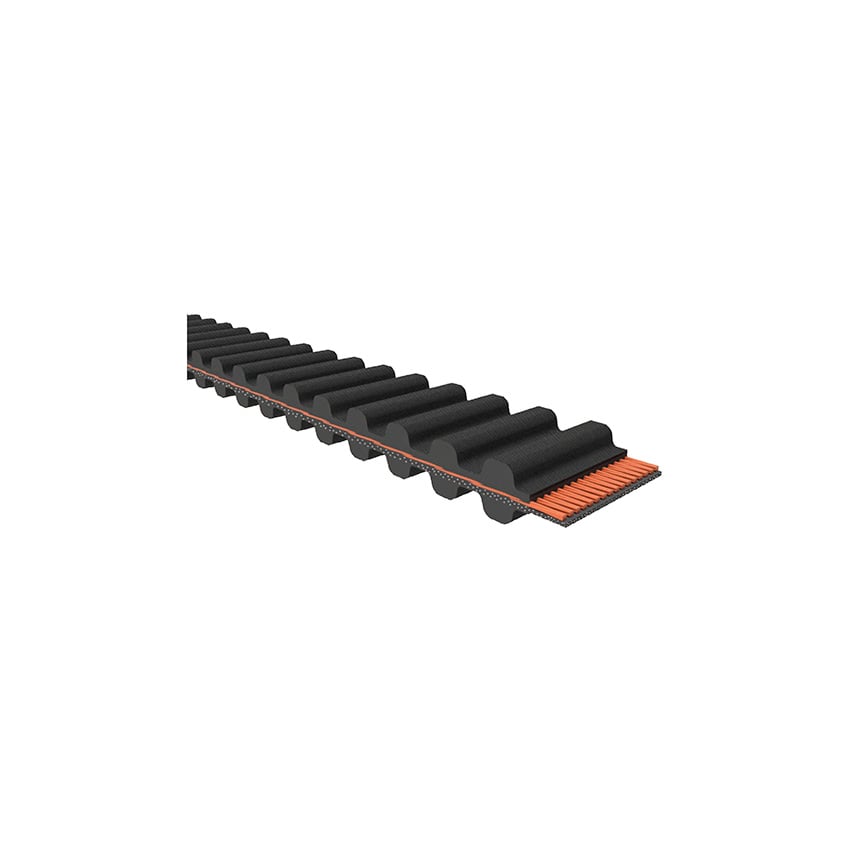

Elite-Extreme Band Wedge

3VX Band

5VX Band

Elite-Extreme Band Wedge Elite

D&D ELITE-EXTREME BAND WEDGE belts meet or exceed USA RMA published rating levels. They are manufactured to perform at identical or higher levels than all major US manufacturer’s belts of the same type.

3VX Band <106’’: 2-12 bands

3VX Band >/106”: 2-8 bands

5VX Band <112’’: 2-8 bands

5VX Band >/=112’’: 2-8 bands

Elite Cogged V-Belts are engineered with high-quality EPDM rubber to resist high heat and oil. Their flexibility reduces the risk of cracking, offering better performance in demanding conditions. Elite belts are produced with Generation 3 Manufacturing and are designed to be reliable and efficient in high-speed operations and transmitting large amounts of power. Our belts are Reach and RoHS compliant, and meet DIN7753 Belt Standards.

DURA ELITE TIMING BELTS

Dura-Sync Torque*

3M

5M

8M

14M

20M

Dura-Sync Torque*

D&D DURA-SYNC TORQUE belts meet or exceed USA RMA published ratings levels. They are manufactured to perform at identical or higher levels than all major US manufacturer’s belts of the same type. They offer a dependable, economical and hassle-free alternative to chain drives.

Available in Elite*, double-sided, and an aramid cord option.

*D&D Elite Timing Belts are produced with Generation 3 manufacturing, using advanced production processes focused on improving quality control, automation, and performance. This precision production creates belts better suited for high speeds and more efficient power transmission, enhancing performance. Elite belts primarily have better heat resistance and flexibility, extending their lifespan in harsh operating conditions.

Dura-Sure Torque*

S1.5M

S2M

S3M

Dura-Sure Torque*

D&D DURA-SURE TORQUE belts meet or exceed USA RMA published ratings levels. They are manufactured to perform at identical or higher levels than all major US manufacturer’s belts of the same type.

Available in Elite*, double-sided, and an aramid cord option.

*D&D Elite Timing Belts are produced with Generation 3 manufacturing, using advanced production processes focused on improving quality control, automation, and performance. This precision production creates belts better suited for high speeds and more efficient power transmission, enhancing performance. Elite belts primarily have better heat resistance and flexibility, extending their lifespan in harsh operating conditions.

Dura-Precision Torque*

P2M

P3M

P5M

P8M

P14M

Dura-Precision Torque*

D&D DURA-PRECISION TORQUE belts meet or exceed USA RMA published rating levels. They are manufactured to perform at identical or higher levels than all major US manufacturer’s belts of the same type.

Available in Elite*, double-sided, and an aramid cord option.

*D&D Elite Timing Belts are produced with Generation 3 manufacturing, using advanced production processes focused on improving quality control, automation, and performance. This precision production creates belts better suited for high speeds and more efficient power transmission, enhancing performance. Elite belts primarily have better heat resistance and flexibility, extending their lifespan in harsh operating conditions.

Dura-Premium Torque*

MXL

XL

L

HL

H

XH

XXH

Dura-Premium Torque*

D&D DURA-PREMIUM TORQUE belts meet or exceed USA RMA published rating levels. They are manufactured to perform at identical or higher levels than all major US Manufacturer’s belts of the same type.

Available in Elite*, double-sided, and an aramid cord option.

* D&D Elite Timing Belts are produced with Generation 3 manufacturing, using advanced production processes focused on improving quality control, automation, and performance. This precision production creates belts better suited for high speeds and more efficient power transmission, enhancing performance. Elite belts primarily have better heat resistance and flexibility, extending their lifespan in harsh operating conditions.

Dura-Absolute Torque*

AT5

AT10

AT20

Dura-Absolute Torque*

D&D DURA-ABSOLUTE TORQUE belts meet or exceed USA RMA published rating levels. They are manufactured to perform at identical or higher levels than all major US manufacturer’s belts of the same type.

Available in Elite*, double-sided, and an aramid cord option.

*D&D Elite Timing Belts are produced with Generation 3 manufacturing, using advanced production processes focused on improving quality control, automation, and performance. This precision production creates belts better suited for high speeds and more efficient power transmission, enhancing performance. Elite belts primarily have better heat resistance and flexibility, extending their lifespan in harsh operating conditions.

Dura-True Torque*

T2.5

T5

T10

T20

Dura-True Torque*

D&D DURA-TRUE TORQUE belts meet or exceed USA RMA published rating levels. They are manufactured to perform at identical or higher levels than all major US manufacturer’s belts of the same type.

Available in Elite*, double-sided, and an aramid cord option.

*D&D Elite Timing Belts are produced with Generation 3 manufacturing, using advanced production processes focused on improving quality control, automation, and performance. This precision production creates belts better suited for high speeds and more efficient power transmission, enhancing performance. Elite belts primarily have better heat resistance and flexibility, extending their lifespan in harsh operating conditions.

Dura-Torque GT*

1.5GT

2GT

3GT

5GT

Dura-Torque GT*

D&D DURA-TORQUE GT belts meet or exceed USA RMA published rating levels. They are manufactured to perform at identical or higher levels than all major US manufacturer’s belts of the same type.

Available in Elite*, double-sided, and an aramid cord option.

*D&D Elite Timing Belts are produced with Generation 3 manufacturing, using advanced production processes focused on improving quality control, automation, and performance. This precision production creates belts better suited for high speeds and more efficient power transmission, enhancing performance. Elite belts primarily have better heat resistance and flexibility, extending their lifespan in harsh operating conditions.

Dura-Yield Free Torque*

8YU

Dura-Yield Free Torque*

D&D DURA-YILED FREE TORQUE belts meet or exceed USA RMA published rating levels. They are manufactured to perform at identical or higher levels than all major US manufacturer’s belts of the same type.

Available in Elite* and double-sided.

*D&D Elite Timing Belts are produced with Generation 3 manufacturing, using advanced production processes focused on improving quality control, automation, and performance. This precision production creates belts better suited for high speeds and more efficient power transmission, enhancing performance. Elite belts primarily have better heat resistance and flexibility, extending their lifespan in harsh operating conditions.

Dura-Sync Torque Ultimate*

3MK

5MK

8MK

S8MK

Dura-Sync Torque Ultimate*

D&D DURA-SYNC TORQUE ULTIMATE belts meet or exceed USA RMA published rating levels. They are manufactured to perform at identical or higher levels than all major US manufacturer’s belts of the same type.

Available in Elite* and double-sided.

*D&D Elite Timing Belts are produced with Generation 3 manufacturing, using advanced production processes focused on improving quality control, automation, and performance. This precision production creates belts better suited for high speeds and more efficient power transmission, enhancing performance. Elite belts primarily have better heat resistance and flexibility, extending their lifespan in harsh operating conditions.

Dura-Premium Torque Ultimate*

XLK

LK

HK

Dura-Premium Torque Ultimate*

D&D DURA-PREMIUM TORQUE ULTIMATE belts meet or exceed USA RMA published rating levels. They are manufactured to perform at identical or higher levels than all major US Manufacturer’s belts of the same type.

Available in Elite* and double-sided.

*D&D Elite Timing Belts are produced with Generation 3 manufacturing, using advanced production processes focused on improving quality control, automation, and performance. This precision production creates belts better suited for high speeds and more efficient power transmission, enhancing performance. Elite belts primarily have better heat resistance and flexibility, extending their lifespan in harsh operating conditions.

DUAL DURA ELITE TIMING BELTS

Dual Dura-Sync Torque*

D3M

D5M

D8M

D14M

D20M

Dual Dura-Sync Torque*

D&D DUAL DURA-SYNC TORQUE belts meet or exceed USA RMA published rating levels. They are manufactured to perform at identical or higher levels than all major US manufacturer’s belts of the same type.

Available in Elite*.

*D&D Elite Timing Belts are produced with Generation 3 manufacturing, using advanced production processes focused on improving quality control, automation, and performance. This precision production creates belts better suited for high speeds and more efficient power transmission, enhancing performance. Elite belts primarily have better heat resistance and flexibility, extending their lifespan in harsh operating conditions.

Dual Dura-Sure Torque*

DS2M

DS3M

DS4.5M

DS5M

DS8M

DS14M

Dual Dura-Sure Torque*

D&D DUAL DURA-SURE TORQUE belts meet or exceed USA RMA published rating levels. They are manufactured to perform at identical or higher levels than all major US manufacturer’s belts of the same type.

Available in Elite*.

*D&D Elite Timing Belts are produced with Generation 3 manufacturing, using advanced production processes focused on improving quality control, automation, and performance. This precision production creates belts better suited for high speeds and more efficient power transmission, enhancing performance. Elite belts primarily have better heat resistance and flexibility, extending their lifespan in harsh operating conditions.

Dual Dura-Precision Torque*

DP2M

DP3M

DP5M

DP8M

DP14M

Dual Dura-Precision Torque*

D&D DUAL DURA-PRECISION TORQUE US belts meet or exceed USA RMA published rating levels. They are manufactured to perform at identical or higher levels than all major US manufacturer’s belts of the same type.

Available in Elite*.

*D&D Elite Timing Belts are produced with Generation 3 manufacturing, using advanced production processes focused on improving quality control, automation, and performance. This precision production creates belts better suited for high speeds and more efficient power transmission, enhancing performance. Elite belts primarily have better heat resistance and flexibility, extending their lifespan in harsh operating conditions.

Dual Dura-Absolute Torque*

AT5

AT10

AT20

Dual Dura-Absolute Torque*

D&D DUAL DURA-ABSOLUTE TORQUE belts meet or exceed USA RMA published rating levels. They are manufactured to perform at identical or higher levels than all major US manufacturer’s belts of the same type.

Available in Elite*.

*D&D Elite Timing Belts are produced with Generation 3 manufacturing, using advanced production processes focused on improving quality control, automation, and performance. This precision production creates belts better suited for high speeds and more efficient power transmission, enhancing performance. Elite belts primarily have better heat resistance and flexibility, extending their lifespan in harsh operating conditions.

Dual Dura-True Torque*

DT2.5

DT5

DT10

DT20

Dual Dura-True Torque*

D&D DUAL DURA-TRUE TORQUE belts meet or exceed USA RMA published rating levels. They are manufactured to perform at identical or higher levels than all major US manufacturer’s belts of the same type.

Available in Elite*.

*D&D Elite Timing Belts are produced with Generation 3 manufacturing, using advanced production processes focused on improving quality control, automation, and performance. This precision production creates belts better suited for high speeds and more efficient power transmission, enhancing performance. Elite belts primarily have better heat resistance and flexibility, extending their lifespan in harsh operating conditions.

Dual Dura Torque GT*

D1.5GT

D2GT

D3GT

D5GT

Dual Dura Torque GT*

D&D DUAL DURA TORQUE GT belts meet or exceed USA RMA published rating levels. They are manufactured to perform at identical or higher levels than all major US manufacturer’s belts of the same type.

Available in Elite*.

*D&D Elite Timing Belts are produced with Generation 3 manufacturing, using advanced production processes focused on improving quality control, automation, and performance. This precision production creates belts better suited for high speeds and more efficient power transmission, enhancing performance. Elite belts primarily have better heat resistance and flexibility, extending their lifespan in harsh operating conditions.

Dual Dura-Sync Torque Ultimate*

Dual Dura-Sync Torque Ultimate*

D&D DUAL DURA-SYNC TORQUE ULTIMATE belts meet or exceed USA RMA published rating levels. They are manufactured to perform at identical or higher levels than all major US manufacturer’s belts of the same type.

Available in Elite*.

*D&D Elite Timing Belts are produced with Generation 3 manufacturing, using advanced production processes focused on improving quality control, automation, and performance. This precision production creates belts better suited for high speeds and more efficient power transmission, enhancing performance. Elite belts primarily have better heat resistance and flexibility, extending their lifespan in harsh operating conditions.

Dual Dura-Premium Torque*

DMXL

DXL

DL

DH

DXH

DXXH

Dual Dura-Premium Torque*

D&D DUAL DURA-PREMIUM TORQUE belts meet or exceed USA RMA published rating levels. They are manufactured to perform at identical or higher levels than all major US manufacturer’s belts of the same type.

Available in Elite*.

*D&D Elite Timing Belts are produced with Generation 3 manufacturing, using advanced production processes focused on improving quality control, automation, and performance. This precision production creates belts better suited for high speeds and more efficient power transmission, enhancing performance. Elite belts primarily have better heat resistance and flexibility, extending their lifespan in harsh operating conditions.