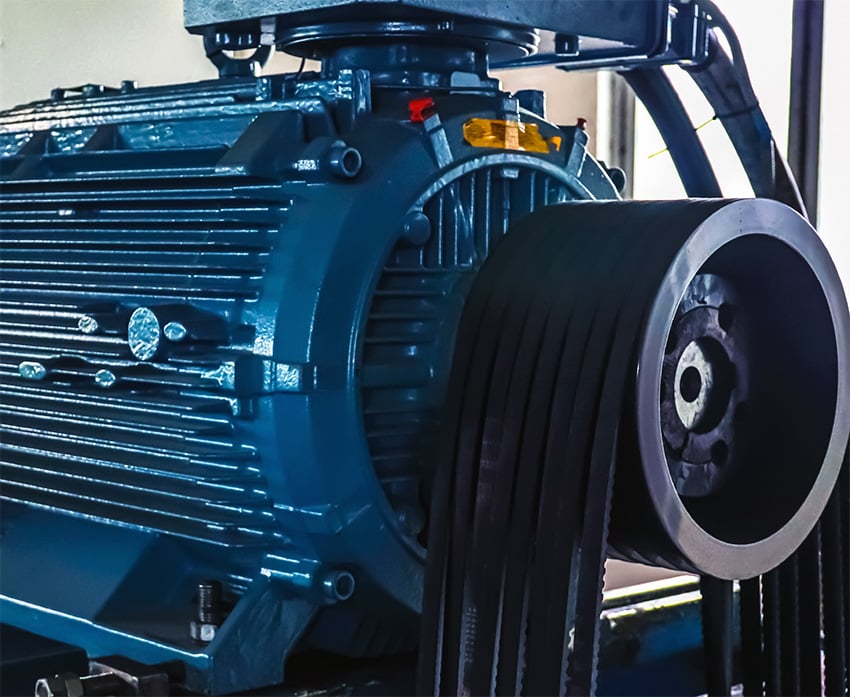

Power Drive Belts for Manufacturers

Reduce Downtime, Secure Inventory & Simplify Belt Sourcing with D&D

When you’re building equipment at scale, a delayed or unreliable belt supplier can bring everything to a halt. D&D Global is a vertically integrated OEM belt manufacturer that helps equipment builders avoid downtime and cut sourcing complexity with dependable power drive belts, V-belts, and timing belts.

From oilfield pumping units to HVAC systems, packaging lines to fitness equipment—manufacturers rely on D&D Global to keep their builds on schedule and their belts in stock.

Why Manufacturers Trust D&D for Power Drive Belts

Reliable Power Drive Belt Inventory

With over 35,000 SKUs stocked across four strategically located warehouses across the U.S., we make sure the belts you need are ready when you need them. We support:

- Scheduled releases

- Pre-purchased and reserved inventory

- Custom inventory programs based on your forecast

Flexible Belt Procurement for Manufacturing

Whether you're sourcing belts under your own brand or need unique part numbers for custom assemblies, D&D delivers:

- Private label and white label belts

- Custom part numbering

- Seasonal forecasting and dynamic reorder points

Focused on Belts. Focused on You.

Unlike general industrial suppliers, D&D only makes belts—and we do it right. From deep cross-referencing to emergency fulfillment, we solve the sourcing headaches manufacturers face every day.

One client replaced failing Gates belts with D&D belts—and saw performance increase from 1-day failures to nearly two weeks of continuous 24/7 runtime.

CASE STUDY

When a Belt Supplier Fails, Production Stops

Time for a Road Trip!

A national manufacturer contacted us in a panic: their supplier dropped the ball, and they were days behind on a major equipment rollout. Within 12 hours, D&D hand-delivered 78 belts across state lines. The next morning, production resumed. Two days later, we had them set up with reserve stock and a scheduled release program.

They’ve been with D&D ever since.

Why Vertical Integration Matters for Manufacturing

We’re a 100% vertically integrated power drive belt manufacturer. That means:

- Faster production cycles

- Consistent quality control

- No outsourcing, no delays

As one manufacturer put it:

“I love it because you don’t have to go outside of anything.”

That’s the D&D difference. We’re just like our partners—self-contained, efficient, and focused on what we do best.

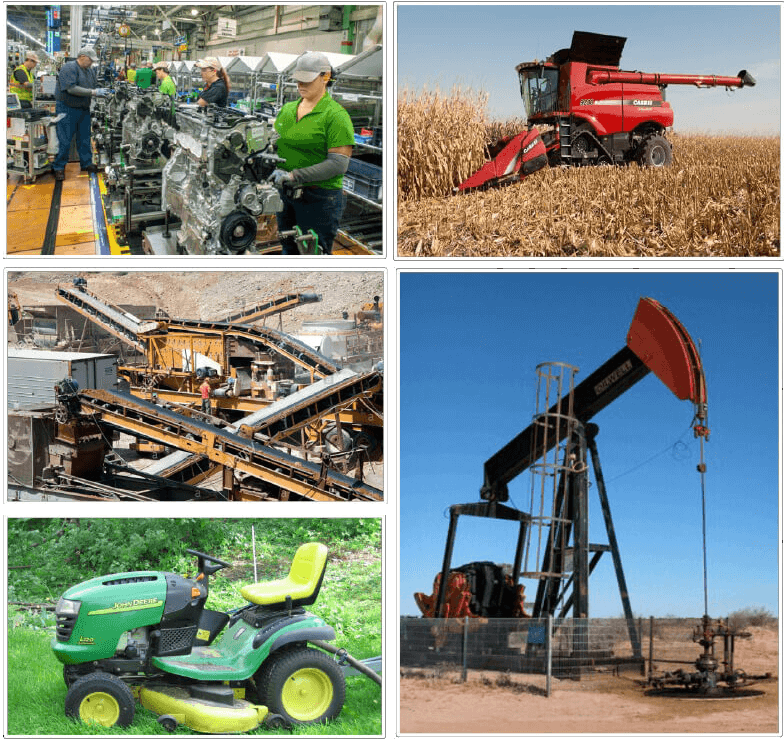

Industries We Supply with Power Drive Belts

We provide power transmission belts for manufacturing applications in:

- Agriculture

- Aggregate

- Automotive

- Construction

- Exercise Equipment

- HVAC

- Oil & Gas

- Lawn & Garden

- Many More!

No Cheap Fillers at D&D

We don’t use recycled materials, clay, talc, or hazardous compounds in our belts.

This means low odor, superior durability, and cleaner air quality.

Many competitors rely on cheap fillers that release toxic VOCs, leading to air pollution, respiratory issues, and faster belt degradation.

With D&D, you get safe, high-performance belts built to last.

Our Power Drive Belts Don't Stink

... because they're made with 100% pure rubber.

Consistency and Durability: Pure rubber offers more consistent material properties, such as uniform tensile strength and elasticity.

Performance in Demanding Conditions: Pure rubber belts perform better under extreme conditions such as high temperatures, heavy loads, and constant wear, because of its unaltered chemical and physical structure.

Flexibility and Resilience: Pure rubber retains superior flexibility and resilience, allowing it to better handle shock loads and resist cracking over time.

Chemical Resistance: Pure rubber is typically formulated to provide excellent resistance to chemicals, oils, and other environmental factors.